Steady-state torsional vibration in the crankshaft of an internal combustion engine

Calculation of the steady-state torsional vibration in the crankshaft of an internal combustion engine. Torque produced by each cylinder is calculated from the force produced by the pressure from ignition which is scaled according to the rotation speed of the crankshaft. Torsional vibration analysis based on the article “Analysis of torsional vibration in internal combustion engines: Modelling and experimental validation” [1]. The model is based on Fig.4 of the original article.

[1]:

import matplotlib.pyplot as plt

import numpy as np

import scipy

import opentorsion

from opentorsion import Shaft, Disk, Assembly

[2]:

def pressure_curve():

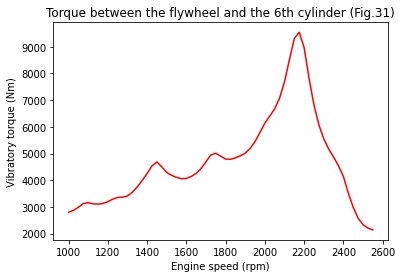

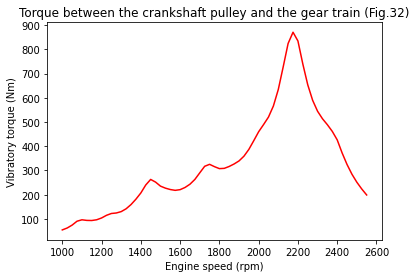

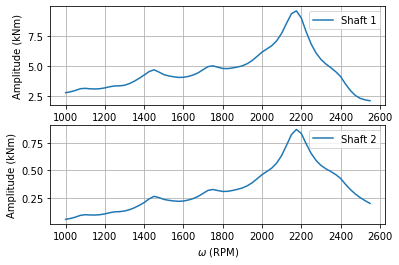

'''Load digitized pressure curve from csv and pass it to interpolator'''

curve = np.genfromtxt('ICE_example_data/pressure_data.csv', delimiter=';')

return scipy.interpolate.interp1d(curve[:, 0], curve[:, 1])

[3]:

def peak_pressures():

'''Load digitized peak pressure from csv and pass it to interpolator'''

curve = np.genfromtxt('ICE_example_data/peak_data.csv', delimiter=';')

return scipy.interpolate.interp1d(curve[:, 0], curve[:, 1])

[4]:

def scaled_cylinder_pressure(rpm, num_points):

'''

Scales the cylinder pressure curve based on the variation

of peak pressure with engine speed.

Arguments

---------

rpm: float

Rotating speed of the engine in rpm

num_points: int

Number of points in x-axis

Returns

-------

angles: np.ndarray

Angles for which the cylinder pressures are given

scaled_curve: np.ndarray

The scaled pressure curve scaled to the given rpm corresponding

to the angles. (Pa)

'''

# Load the base pressure curve

angles = np.linspace(0, 720, num_points)

base_curve = pressure_curve()

base_curve_sampled = base_curve(angles)/15.2

# Scale with the peak pressure

pressures = peak_pressures()

scaling = pressures(rpm)

scaled_curve = base_curve_sampled*scaling*1e6

return angles, scaled_curve

[5]:

def calculate_cylinder_torque(speed_rpm, num_points=500):

'''

Calculates the torque produced by a single cylinder at given rpm.

Torque is based on the tangential force caused by the pressure in the cylinder and the tangential component

of the oscillating inertial force from the crankshaft spinning.

Parameters

----------

speed_rpm: float

Current rotation speed in rpm

num_points: float, optional

Number of points for the x-axis

Returns

-------

M_t: ndarray

The torque produced by the cylinder

alpha: ndarray

Angles for which the cylinder torques are given

'''

def alpha_to_beta(alpha, r, l_rod):

return np.arcsin(r/l_rod * np.sin(alpha))

l_rod = 0.207 # m

d_piston = 0.105 # m

r = 0.137 / 2 # m (piston stroke / 2) crankshaft radius

m_a = 2.521 # kg

alpha_deg, p_curve = scaled_cylinder_pressure(speed_rpm, num_points)

alpha = alpha_deg/180*np.pi

w = speed_rpm/60*2*np.pi

F_g = p_curve * 0.25*np.pi*d_piston**2

beta = alpha_to_beta(alpha, r, l_rod)

F_tg = F_g * np.sin(alpha + beta) * 1/np.cos(beta) # Tangential gas load

lambda_rl = r/l_rod

F_ia = -m_a*r*(np.cos(alpha)

+ lambda_rl*np.cos(2*alpha)

- lambda_rl**3*1/4 * np.cos(4*alpha)

+ 9*lambda_rl**5*np.cos(6*alpha)/128)*w**2 # Oscillating inertial force

F_ta = F_ia * np.sin(alpha + beta) * 1/np.cos(beta) # Tangential inertial force

F_t = F_tg + F_ta # Total tangential force

M_t = F_t * r

return M_t, alpha

[6]:

def calculate_dft_components(signal, t, num_harmonics):

'''

Calculates dft components and harmonics (0,0.5,1,...) for the given signal, to be used at stedy-state

vibration calculations.

Parameters

----------

signal: ndarray

Cylinder torque

t: ndarray

Crankshaft rotation angle

num_harmonics: float

Number of harmonics considered

Returns

-------

complex ndarray

The first num_harmonics complex components of the Fourier transform

complex ndarray

The first num_harmonics components of the harmonics

'''

dft = np.fft.rfft(signal)/len(signal)

dft[1:] *= 2

omegas = np.fft.rfftfreq(len(signal))*1/(t[1]-t[0])*2*np.pi

return [dft[:num_harmonics], omegas[:num_harmonics]]

[7]:

def crankshaft_assembly():

'''

A shaft-line Finite Element Model of a crankshaft based on model presented

in https://doi.org/10.1243/14644193JMBD126 Fig.4.

Returns

-------

assembly: openTorsion Assembly class instance

The created opentorsion assembly

'''

J2 = 0.0170

J3 = 0.0090

J4 = 0.0467

J5 = 0.0327

J6 = 0.0467

J7 = 0.0467

J8 = 0.0327

J9 = 0.0487

J10 = 2.0750

k2 = 1.106e6

k3 = 1.631e6

k4 = 1.253e6

k5 = 1.253e6

k6 = 1.678e6

k7 = 1.253e6

k8 = 1.253e6

k9 = 1.976e6

c_a = 2 # absolute damping

shafts, disks = [], []

disks.append(Disk(0, J2))

shafts.append(Shaft(0, 1, None, None, k=k2, I=0))

disks.append(Disk(1, J3))

shafts.append(Shaft(1, 2, None, None, k=k3, I=0))

disks.append(Disk(2, J4, c=c_a)) # cylinder 1

shafts.append(Shaft(2, 3, None, None, k=k4, I=0))

disks.append(Disk(3, J5, c=c_a))

shafts.append(Shaft(3, 4, None, None, k=k5, I=0))

disks.append(Disk(4, J6, c=c_a))

shafts.append(Shaft(4, 5, None, None, k=k6, I=0))

disks.append(Disk(5, J7, c=c_a))

shafts.append(Shaft(5, 6, None, None, k=k7, I=0))

disks.append(Disk(6, J8, c=c_a))

shafts.append(Shaft(6, 7, None, None, k=k8, I=0))

disks.append(Disk(7, J9, c=c_a)) #cylinder 6

shafts.append(Shaft(7, 8, None, None, k=k9, I=0))

disks.append(Disk(8, J10)) # flywheel

assembly = Assembly(shafts, disk_elements=disks)

return assembly

[8]:

def relative_damping_C(assembly, d, w):

'''

Updates the damping matrix C of assembly when using frequency dependent relative damping.

Parameters

----------

assembly: openTorsion Assembly class instance

The assembly of whose damping matrix is to be updated

d: float

Loss factor property, used to calculate relative damping

w: float

Angular frequency of the system, used to calculate relative damping

Returns

-------

C: ndarray

The damping matrix assembled with new component specific damping coefficients

'''

if w!=0:

c_r = d/w

else:

c_r = 0

C = np.zeros((assembly.check_dof(), assembly.check_dof()))

if assembly.shaft_elements is not None:

for element in assembly.shaft_elements:

dof = np.array([element.nl, element.nr])

C[np.ix_(dof, dof)] += c_r*element.K()

if assembly.disk_elements is not None:

for element in assembly.disk_elements:

C[element.node, element.node] += element.C()

if assembly.gear_elements is not None:

for element in assembly.gear_elements:

C[element.node, element.node] += element.C()

# Build transformation matrix

E = assembly.E()

transform = assembly.T(E)

# Calculate transformed mass matrix

C = np.dot(np.dot(transform.T, C), transform)

return C

[9]:

def calculate_response(crankshaft, rpm):

'''

Calculates the crankshaft's response to excitation at given rpm.

Parameters

----------

crankshaft: openTorsion Assembly class instance

Opentorsion Assembly of the crankshaft

rpm: float

Current rotation speed in rpm

Returns

-------

sum_response: ndarray

Array containing maximum vibratory torque at current rotation speed for each shaft

'''

dof = 9

cylinder_torque, alpha = calculate_cylinder_torque(rpm)

dft_parameters, harmonics = calculate_dft_components(cylinder_torque, alpha, 25)

q = np.zeros([dof, len(harmonics)], dtype='complex128')

M = crankshaft.M

K = crankshaft.K

d = 0.035

for i in range(len(harmonics)):

# build T vector

offset = 2 # offset to the first cylinder

phase_shift = 2/3*np.pi

T = np.zeros(dof, dtype='complex128')

T[offset] = dft_parameters[i]

T[offset+1] = dft_parameters[i]*np.exp( 2.0j*phase_shift*harmonics[i])

T[offset+2] = dft_parameters[i]*np.exp(-2.0j*phase_shift*harmonics[i])

T[offset+3] = dft_parameters[i]*np.exp( 1.0j*phase_shift*harmonics[i])

T[offset+4] = dft_parameters[i]*np.exp(-1.0j*phase_shift*harmonics[i])

T[offset+5] = dft_parameters[i]*np.exp( 3.0j*phase_shift*harmonics[i])

w = harmonics[i]*rpm*2*np.pi/60

C = relative_damping_C(crankshaft, d, w)

receptance = np.linalg.inv(-w**2*M+1.0j*w*C+K)

q.T[i] = receptance @ T

# Calculate the angle difference between two consecutive disks

q_difference = (q.T[:, 1:] - q.T[:, :-1]).T

shaft_list = crankshaft.shaft_elements

shaft_ks = np.array([shaft.k for shaft in shaft_list])

# Multiply the angle difference between two disks with the connecting shaft stiffness to get

# the torque in the shaft

q_response = (shaft_ks*q_difference.T).T

for i in range(dof-1):

shaft_i = q_response[i]

sum_wave = np.zeros_like(alpha)

for i in range(len(shaft_i)):

this_wave = np.real(shaft_i[i]*np.exp(1.0j*harmonics[i]*alpha))

sum_wave += this_wave

sum_response = np.sum(np.abs(q_response), axis=1)

return sum_response

[10]:

def plot_results(rpms, vibratory_torque):

'''

Plots the vibratory torque in wanted shafts for each considered engine speed.

Parameters

----------

rpms: ndarray

All considered engine speeds in rpm

vibratory_torque: ndarray

Matrix containing maximum vibratory torque at each rotation speed for each shaft.

Each row correspond to an engine speed and each column to a shaft.

Returns

-------

shaft_8: ndarray

Array containing maximum vibratory torque at all considered engine speeds for shaft

between flywheel and 6th cylinder

shaft_1: ndarray

Array containing maximum vibratory torque at all considered engine speeds for shaft

between crankshaft pulley and gear train

'''

shaft_8 = [shaft[7] for shaft in vibratory_torque]

plt.plot(rpms, shaft_8, c='red', label='calculated')

plt.xlabel('Engine speed (rpm)')

plt.ylabel('Vibratory torque (Nm)')

plt.title('Torque between the flywheel and the 6th cylinder (Fig.31)')

plt.figure()

shaft_1 = [shaft[0] for shaft in vibratory_torque]

plt.plot(rpms, shaft_1, c='red', label='calculated')

plt.xlabel('Engine speed (rpm)')

plt.ylabel('Vibratory torque (Nm)')

plt.title('Torque between the crankshaft pulley and the gear train (Fig.32)')

plt.figure()

return shaft_8, shaft_1

[11]:

assembly = crankshaft_assembly()

rpms = np.arange(1000, 2575, 25)

# Vibratory torque for every shaft and every considered engine speed

vibratory_torque = []

for rpm in rpms:

vibratory_torque.append(calculate_response(assembly, rpm))

shaft_8, shaft_1 = plot_results(rpms, vibratory_torque)

# Same plots but using openTorsions Plots class

plots = opentorsion.Plots(assembly)

plots.torque_response_plot(rpms, [np.array(shaft_8), np.array(shaft_1)], True)

[1] Mendes AS, Meirelles PS, Zampieri DE. Analysis of torsional vibration in internal combustion engines: Modelling and experimental validation. Proceedings of the Institution of Mechanical Engineers, Part K: Journal of Multi-body Dynamics. 2008;222(2):155-178. doi:10.1243/14644193JMBD126